Projects

Archive

IRiS

Interactive Robotic System for Unloading of Sea Containers

40-foot standard containers are the most common sea containers worldwide. With their internal dimensions of around 12 by 2.3 by 2.4 metres, they have a loading volume of a good 65 cubic metres and a payload of around 26 tonnes. Emptying these containers is a heavy job that is still largely manual in the ports today. In the future, it will be done with the help of a new type of robot. The BIBA - Bremen Institut für Produktion und Logistik at the University of Bremen is conducting research with its development partners BLG Handelslogistik and SCHULZ Systemtechnik from Bremen and FRAMOS from Taufkirchen in the new project "Interactive Robotic System for Emptying Sea Containers" (IRiS).

The project aims to improve working conditions and the efficiency of transhipment processes at seaports. The novel mobile robot developed in the project should be able to be used for unloading within a very short time without major adaptations in the existing operational infrastructure. It will be able to move self-propelled between several doors and, as the container is gradually emptied, will be able to enter the container and will have a new kinematics and gripping system. Established methods of machine learning enable the robot to classify and optimally unload different packing scenarios.

The German Federal Ministry of Transport and Digital Infrastructure (BMVI) is funding this three-year project with 2.2 million euros as part of the Innovative Port Technologies Programme (IHATEC). The total volume amounts to 3.16 million euros. The project is supported by the project management organisation TÜV Rheinland, and BLG Handelslogistik as network coordinator

Project Leader LogDynamics: Prof. Dr.-Ing. Michael Freitag

» www.iris-projekt.de

40-foot standard containers are the most common sea containers worldwide. With their internal dimensions of around 12 by 2.3 by 2.4 metres, they have a loading volume of a good 65 cubic metres and a payload of around 26 tonnes. Emptying these containers is a heavy job that is still largely manual in the ports today. In the future, it will be done with the help of a new type of robot. The BIBA - Bremen Institut für Produktion und Logistik at the University of Bremen is conducting research with its development partners BLG Handelslogistik and SCHULZ Systemtechnik from Bremen and FRAMOS from Taufkirchen in the new project "Interactive Robotic System for Emptying Sea Containers" (IRiS).

The project aims to improve working conditions and the efficiency of transhipment processes at seaports. The novel mobile robot developed in the project should be able to be used for unloading within a very short time without major adaptations in the existing operational infrastructure. It will be able to move self-propelled between several doors and, as the container is gradually emptied, will be able to enter the container and will have a new kinematics and gripping system. Established methods of machine learning enable the robot to classify and optimally unload different packing scenarios.

The German Federal Ministry of Transport and Digital Infrastructure (BMVI) is funding this three-year project with 2.2 million euros as part of the Innovative Port Technologies Programme (IHATEC). The total volume amounts to 3.16 million euros. The project is supported by the project management organisation TÜV Rheinland, and BLG Handelslogistik as network coordinator

Project Leader LogDynamics: Prof. Dr.-Ing. Michael Freitag

» www.iris-projekt.de

EASE

Collaborative Research Center “Everyday Activity Science and Engineering

"Please set the table!" – many instructions, which are easy for humans to implement, present robots with enormous challenges. In order to carry out activities, they need extremely detailed information: what should be placed on the table? How to best grab a glass? And how do you recognize a table at all? In order for robots to be able to execute statements with a high degree of abstraction independently, they must be able to obtain missing information themselves. The German Research Foundation (DFG) has now approved a further Collaborative Research Center (CRC) at the University of Bremen, where scientists are working with completely new approaches to the fact that robots implement abstract instructions independently. They enable them to learn. The CRC EASE (Everyday Activity Science and Engineering) was launched on July 1, 2017 and is financed by the DFG for 10 years at its first funding phase. Several LogDynamics members are involved in the CRC.

Within the framework of basic research, EASE will examine how people manage their day-to-day activities in an extremely flexible, reliable and efficient manner. This understanding is then intended to inspire a new generation of robot control models to achieve a comparable level. "When robots learn how to properly interpret colloquial instructions, there are numerous possibilities for increasing the quality of life - for example for people with disabilities or for seniors who want to live independently in their own four walls," explains the CRC speaker, Professor Michael Beetz. A wide range of possible applications are also conceivable in research, including carrying out experiments with hazardous substances. Procejt Leader LogDynamics: Prof. Michael Beetz PhD

» www.ease-crc.org

"Please set the table!" – many instructions, which are easy for humans to implement, present robots with enormous challenges. In order to carry out activities, they need extremely detailed information: what should be placed on the table? How to best grab a glass? And how do you recognize a table at all? In order for robots to be able to execute statements with a high degree of abstraction independently, they must be able to obtain missing information themselves. The German Research Foundation (DFG) has now approved a further Collaborative Research Center (CRC) at the University of Bremen, where scientists are working with completely new approaches to the fact that robots implement abstract instructions independently. They enable them to learn. The CRC EASE (Everyday Activity Science and Engineering) was launched on July 1, 2017 and is financed by the DFG for 10 years at its first funding phase. Several LogDynamics members are involved in the CRC.

Within the framework of basic research, EASE will examine how people manage their day-to-day activities in an extremely flexible, reliable and efficient manner. This understanding is then intended to inspire a new generation of robot control models to achieve a comparable level. "When robots learn how to properly interpret colloquial instructions, there are numerous possibilities for increasing the quality of life - for example for people with disabilities or for seniors who want to live independently in their own four walls," explains the CRC speaker, Professor Michael Beetz. A wide range of possible applications are also conceivable in research, including carrying out experiments with hazardous substances. Procejt Leader LogDynamics: Prof. Michael Beetz PhD

» www.ease-crc.org

bIoTope

Building an IoT open innovation ecosystem for connected smart objects

IT systems can observe traffic flows and fine dust pollution as well as control traffic lights, snow shoveling services and power supply. Moreover, they can guarantee safe ways to school and optimized waste disposal as well as inform about available parking spaces or e-car charging stations. In the City of the Future, these IT systems, which already ease our lives nowadays, have to collaborate together. A European project with 22 partners from 10 countries should establish the basics for City of the Future. The BIBA – Bremer Institut für Produktion und Logistik of the University of Bremen is one of these partners.

The joint project is called bIoTope – 'building an IoT open innovation ecosystem for connected smart objects'. It aims at developing an open Internet-of-Things (IoT) Ecosystem in order to include intelligent objects universally and to connect the countless and still isolated working networks and systems. Life in the City of the Future should be greener, saver and easier, is the vision of bloTope as also declared as the main goal of the EU. Therefore the European Commission supports this project under the scope of Horizon 2020 program.

For sustainable development of IoT projects like bIoTope, the BIBA has founded together with the University of Bremen and its strategic partner Holonix (amongst others) the iotfablab, a fabrication laboratory for IoT components. iotfablab should assist IoT projects and ease access to new technologies for small and medium-sized companies. In addition to this network, the worldwide operating standardization organization 'The Open Group', in which BIBA Institute participates, supports this EU-joint project. It is considered that the global standardization as an essential cornerstone for the use of IoT and for the realization of visions like the one from bloTope.

Project Leader LogDynamics: Prof. Dr.-Ing. Klaus-Dieter Thoben, Prof. Dr.-Ing. Michael Freitag

» www.biotope.cs.hut.fi

IT systems can observe traffic flows and fine dust pollution as well as control traffic lights, snow shoveling services and power supply. Moreover, they can guarantee safe ways to school and optimized waste disposal as well as inform about available parking spaces or e-car charging stations. In the City of the Future, these IT systems, which already ease our lives nowadays, have to collaborate together. A European project with 22 partners from 10 countries should establish the basics for City of the Future. The BIBA – Bremer Institut für Produktion und Logistik of the University of Bremen is one of these partners.

The joint project is called bIoTope – 'building an IoT open innovation ecosystem for connected smart objects'. It aims at developing an open Internet-of-Things (IoT) Ecosystem in order to include intelligent objects universally and to connect the countless and still isolated working networks and systems. Life in the City of the Future should be greener, saver and easier, is the vision of bloTope as also declared as the main goal of the EU. Therefore the European Commission supports this project under the scope of Horizon 2020 program.

For sustainable development of IoT projects like bIoTope, the BIBA has founded together with the University of Bremen and its strategic partner Holonix (amongst others) the iotfablab, a fabrication laboratory for IoT components. iotfablab should assist IoT projects and ease access to new technologies for small and medium-sized companies. In addition to this network, the worldwide operating standardization organization 'The Open Group', in which BIBA Institute participates, supports this EU-joint project. It is considered that the global standardization as an essential cornerstone for the use of IoT and for the realization of visions like the one from bloTope.

Project Leader LogDynamics: Prof. Dr.-Ing. Klaus-Dieter Thoben, Prof. Dr.-Ing. Michael Freitag

» www.biotope.cs.hut.fi

Prof. Drechsler Participates in the New DFG Project 'Farbige Zustände'

The German Research Foundation (DFG) has funded the reserach of Collaborative Research Centre (SFB) 'Von farbigen Zuständen zu evolutionären Konstruktionsmaterialien' under the leadership of the process engineer Prof. Lutz Mädler from the Faculty of Production Engineering with 10 million Euros.

The SFB intents to develop a new method for material development. For this purpose, approaches from biomedical and chemical research shall be transferred to the development of construction materials. Instead of using conventional time-consuming examinations to determine microstructural and mechanical material properties, the SFB aims to develop a new high-throughput technology for construction materials. The interdisciplinary research team combines the research areas process engineering, production engineering, materials engineering, informatics, mathematics as well as planning and logistics. Within this project, the working group computer architecture (AGRA) of the University of Bremen under the leadership of LogDynamics member Prof. Drechsler is responsible for two subprojects, 'predictor function' and 'heuristic, static and analytical experiment design'.

Project Leader LogDynamics: Prof. Dr. Rolf Drechsler

» www.uni-bremen.de/farbige-zustaende

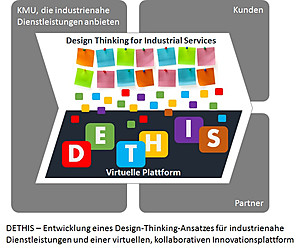

DETHIS

Design Thinking for Industrial Services

In the next three years, scientist from the University of Bremen and six other partners from research and the industry will work on the research project 'DETHIS – Design Thinking for Industrial Services'. The joint project aims at increasing the innovation capability of small and medium-sized firms. The focus is particularly on companies that offer services in the industrial sector. Especially adapted to the innovation of industrial services, a Design-Thinking-Approach and a supporting online platform will be developed, tested and evaluated. In the course of the project, the University of Bremen's team, led by Prof. Jens Pöppelbuß explores how service innovation processes in practice can be improved by the gradual introduction and testing of methods from the adapted Design-Thinking-Methodology Toolbox as well as using the DETHIS platform.

Besides the University of Bremen, project partners are: the Technical University of Braunschweig, Jacobs University Bremen gGmbH, the University of Duisburg-Essen and the companies HPKJ Hydraulik-Pneumatik-Kontor Jade GmbH, Kothes! Technische Kommunikation GmbH & Co. KG and Virtimo AG. The project is funded by the Federal Ministry of Education and Research (BMBF) with about 1.5 million Euro. The coordinating institution is the German Aerospace Center (DLR).

Project Leader LogDynamics: Prof. Dr. Jens Pöppelbuß

» www.dethis.de

In the next three years, scientist from the University of Bremen and six other partners from research and the industry will work on the research project 'DETHIS – Design Thinking for Industrial Services'. The joint project aims at increasing the innovation capability of small and medium-sized firms. The focus is particularly on companies that offer services in the industrial sector. Especially adapted to the innovation of industrial services, a Design-Thinking-Approach and a supporting online platform will be developed, tested and evaluated. In the course of the project, the University of Bremen's team, led by Prof. Jens Pöppelbuß explores how service innovation processes in practice can be improved by the gradual introduction and testing of methods from the adapted Design-Thinking-Methodology Toolbox as well as using the DETHIS platform.

Besides the University of Bremen, project partners are: the Technical University of Braunschweig, Jacobs University Bremen gGmbH, the University of Duisburg-Essen and the companies HPKJ Hydraulik-Pneumatik-Kontor Jade GmbH, Kothes! Technische Kommunikation GmbH & Co. KG and Virtimo AG. The project is funded by the Federal Ministry of Education and Research (BMBF) with about 1.5 million Euro. The coordinating institution is the German Aerospace Center (DLR).

Project Leader LogDynamics: Prof. Dr. Jens Pöppelbuß

» www.dethis.de

CyProS - Cyber Physical Production Systems

Enhancement of Productivity and Flexibility by Networking Intelligent Systems in the Factory

Individualized products and decreasing innovation cycles lead to high challenges for producing companies. Especially the reaction capacity concerning evolving market conditions has to be expanded so as to stand a chance in global competition in the future. This compares with a lacking transparency as well as an insufficient flexibility of the producing companies nowadays. This is where the research program “research for the production of tomorrow” which is funded by the German Federal Ministry of Education and Research (BMBF) comes in. It is part of the field of research intelligent networking in production – a contribution to the future project “Industry 4.0” and thus introduces the fourth industrial revolution. The aim of the research projects is to introduce Cyber-Physical Systems in Production and Logistics.

In the project the BIBA institute is developing a Cyber Physical Logistics System in which autonomous control methods are adapted so that for example “Cyber Physical Workpiece Carriers” can take over controlling tasks and can react to disruptions on short notice. The necessary information for controlling is exchanged in an automatized way between the Cyber Physical Systems (workpiece carriers, conveyors, machines etc.). Furthermore, the employees are integrated into the information flow through mobile assistance systems. Within the duration of the project the Cyber Physical Logistics System is implemented and evaluated prototypically in an industrial application. The BIBA is developing a mechanism to integrate data semantically so as to integrate the different Cyber Physical Systems in the existing, heterogeneous IT-structure of factories and to enable the communication between the CPS. The service-orientated integration approach enables a communication which is independent from interfaces and data formats.

Project Leader LogDynamics: Prof. Dr.-Ing. Klaus-Dieter Thoben

» www.projekt-cypros.de

Individualized products and decreasing innovation cycles lead to high challenges for producing companies. Especially the reaction capacity concerning evolving market conditions has to be expanded so as to stand a chance in global competition in the future. This compares with a lacking transparency as well as an insufficient flexibility of the producing companies nowadays. This is where the research program “research for the production of tomorrow” which is funded by the German Federal Ministry of Education and Research (BMBF) comes in. It is part of the field of research intelligent networking in production – a contribution to the future project “Industry 4.0” and thus introduces the fourth industrial revolution. The aim of the research projects is to introduce Cyber-Physical Systems in Production and Logistics.

In the project the BIBA institute is developing a Cyber Physical Logistics System in which autonomous control methods are adapted so that for example “Cyber Physical Workpiece Carriers” can take over controlling tasks and can react to disruptions on short notice. The necessary information for controlling is exchanged in an automatized way between the Cyber Physical Systems (workpiece carriers, conveyors, machines etc.). Furthermore, the employees are integrated into the information flow through mobile assistance systems. Within the duration of the project the Cyber Physical Logistics System is implemented and evaluated prototypically in an industrial application. The BIBA is developing a mechanism to integrate data semantically so as to integrate the different Cyber Physical Systems in the existing, heterogeneous IT-structure of factories and to enable the communication between the CPS. The service-orientated integration approach enables a communication which is independent from interfaces and data formats.

Project Leader LogDynamics: Prof. Dr.-Ing. Klaus-Dieter Thoben

» www.projekt-cypros.de

SMITH

Energy-efficient supply chain management using expert systems identifying and responding to incidents of passive temperature-controlled transport and handling processes

The project SMITH focuses the issue of passive temperature control using the example of the Aleris Recycling GmbH which organizes transports of liquid aluminum. Within the logistics of Aleris, the liquid aluminum and the corresponding transport containers need to be heated in a way, which guarantees the customer a delivery in a proper processing temperature. Setting the temperature is currently based on experience, using information like the transport time and the condition of the transport container or weather conditions such as outdoor temperature, wind speed and density of precipitation. SMITH addresses these temperatures of the aluminium melt and the transport containers during the shipment and delivery. The project focuses on measures to optimize the heating temperatures and reduce energy costs.

Against this backdrop, the aim of SMITH is to improve the energy efficiency of passive temperature-controlled logistics in the low-temperature and the high-temperature range - first analyzing the transport of liquid aluminum. An expert system is developed that supports shippers and logistics service providers in their decision on the starting temperature of the transported goods. The software predicts the optimum temperature for specific applications based on current factors such as material properties or transport and weather conditions. For the configuration of the expert system and to collect real data from the passive temperature-controlled transports of Aleris, a multi-sensory tool including data storage and data transmission is developed.

With the launch of the expert system for the German production sites, Aleris as a pilot user expects to reduce energy consumption and CO2 emissions significantly. A transfer of the solution to other systems such as the temperature-controlled transport of food enables huge energy and CO2 savings and is an important contribution of the logistics industry to climate protection.

Project Leader LogDynamics: Prof. Dr. Hans-Dietrich Haasis

» www.smith.isl.org

» www.isl.org/projects/smith

The project SMITH focuses the issue of passive temperature control using the example of the Aleris Recycling GmbH which organizes transports of liquid aluminum. Within the logistics of Aleris, the liquid aluminum and the corresponding transport containers need to be heated in a way, which guarantees the customer a delivery in a proper processing temperature. Setting the temperature is currently based on experience, using information like the transport time and the condition of the transport container or weather conditions such as outdoor temperature, wind speed and density of precipitation. SMITH addresses these temperatures of the aluminium melt and the transport containers during the shipment and delivery. The project focuses on measures to optimize the heating temperatures and reduce energy costs.

Against this backdrop, the aim of SMITH is to improve the energy efficiency of passive temperature-controlled logistics in the low-temperature and the high-temperature range - first analyzing the transport of liquid aluminum. An expert system is developed that supports shippers and logistics service providers in their decision on the starting temperature of the transported goods. The software predicts the optimum temperature for specific applications based on current factors such as material properties or transport and weather conditions. For the configuration of the expert system and to collect real data from the passive temperature-controlled transports of Aleris, a multi-sensory tool including data storage and data transmission is developed.

With the launch of the expert system for the German production sites, Aleris as a pilot user expects to reduce energy consumption and CO2 emissions significantly. A transfer of the solution to other systems such as the temperature-controlled transport of food enables huge energy and CO2 savings and is an important contribution of the logistics industry to climate protection.

Project Leader LogDynamics: Prof. Dr. Hans-Dietrich Haasis

» www.smith.isl.org

» www.isl.org/projects/smith

preInO - pre-acting maintenance

Artificial Intelligence for Offshore Wind Energy Plants

Artificial intelligence and automatic self-organisation can optimise maintenance and repair procedures at sea. This is the aim of the new project “preInO” for offshore wind energy plants that the Bremen Institute for Production and Logistics (BIBA) has recently started at the University of Bremen. The project is supported by the Federal Ministry for Environment, Nature Conservation and Reactor Safety and is funded with 1,3 million Euros for three years. With the collaboration of the wind turbine manufacturer REpower Systems SE from Hamburg and the software developer SWMS from Oldenburg, the consortium plans to achieve a “pre-acting maintenance” of offshore wind energy plants. So far, maintenance and repair work of the plants at sea was carried out in fixed cycles or in cases of malfunctioning systems. The increasing number of plants, a varying energy demand and possible standstills call for an optimisation in the deployment of personnel, replacement parts and transportation.

The coordination of material and deployment is of vital importance in the offshore wind industry. For the planning, several factors must be taken into consideration, such as weather conditions, the technical qualification of the employees, the procurement of spare parts, helicopter operations and mandatory contractual terms. Every delay holds a huge cost potential. With “preInO”, BIBA wants to create a control system that uses all available data to assess the condition of a wind park de-centrally and independently, evaluate the urgency of the tasks, calculate risks, estimate the extent of maintenance, organise work schedules and initiate the necessary logistics. The consortium of BIBA, SWMS and REpower systems SE combines its longstanding expertise and competence to this end.

Project Leader LogDynamics: Prof. Dr.-Ing. Klaus-Dieter Thoben

» www.preino.de

Artificial intelligence and automatic self-organisation can optimise maintenance and repair procedures at sea. This is the aim of the new project “preInO” for offshore wind energy plants that the Bremen Institute for Production and Logistics (BIBA) has recently started at the University of Bremen. The project is supported by the Federal Ministry for Environment, Nature Conservation and Reactor Safety and is funded with 1,3 million Euros for three years. With the collaboration of the wind turbine manufacturer REpower Systems SE from Hamburg and the software developer SWMS from Oldenburg, the consortium plans to achieve a “pre-acting maintenance” of offshore wind energy plants. So far, maintenance and repair work of the plants at sea was carried out in fixed cycles or in cases of malfunctioning systems. The increasing number of plants, a varying energy demand and possible standstills call for an optimisation in the deployment of personnel, replacement parts and transportation.

The coordination of material and deployment is of vital importance in the offshore wind industry. For the planning, several factors must be taken into consideration, such as weather conditions, the technical qualification of the employees, the procurement of spare parts, helicopter operations and mandatory contractual terms. Every delay holds a huge cost potential. With “preInO”, BIBA wants to create a control system that uses all available data to assess the condition of a wind park de-centrally and independently, evaluate the urgency of the tasks, calculate risks, estimate the extent of maintenance, organise work schedules and initiate the necessary logistics. The consortium of BIBA, SWMS and REpower systems SE combines its longstanding expertise and competence to this end.

Project Leader LogDynamics: Prof. Dr.-Ing. Klaus-Dieter Thoben

» www.preino.de

PreparedNET

Agent-based simulation and exploration of an emergency concept for the protection of sensitive logistics hubs

The underlying security scenario of the project PreparedNET, funded by the Federal Ministry of Education and Research (BMBF) assumes a disturbance of a freight village by terrorist acts as well as general damages by unforeseen incidents. The goal of PreparedNET is to explore an emergency concept to maintain the flow of goods. In case of a serious disturbance, an emergency operation plan should act immediately. A software-based simulation model is developed, based on a so-called multi-agent system. This reflects not only the incident, but also provides a quick, automated decision support for the freight village actors.

In the simulation model specific characteristics and roles for the control and emergency operation will be assigned to the actors in a freight village. In addition, relevant background information will be used, such as infrastructure and storage capacity, inventory levels, organizational structures and problem solving strategies. If there is a failure, for example to a deterioration of the rail mode, the condition will change and adjust it automatically for the freight village. The system allows not only the necessary process adjustments, but also shows recovery measures that are able to compensate the consequences of an incident as quickly as possible. This dynamic reaction concerning supply bottlenecks in freight villages cannot be achieved by current emergency plans which are often inadequate and rigid.

Project Leader LogDynamics: Prof. Dr. Hans-Dietrich Haasis

» www.preparednet.isl.org

» www.isl.org/en/projects/prepared-net

The underlying security scenario of the project PreparedNET, funded by the Federal Ministry of Education and Research (BMBF) assumes a disturbance of a freight village by terrorist acts as well as general damages by unforeseen incidents. The goal of PreparedNET is to explore an emergency concept to maintain the flow of goods. In case of a serious disturbance, an emergency operation plan should act immediately. A software-based simulation model is developed, based on a so-called multi-agent system. This reflects not only the incident, but also provides a quick, automated decision support for the freight village actors.

In the simulation model specific characteristics and roles for the control and emergency operation will be assigned to the actors in a freight village. In addition, relevant background information will be used, such as infrastructure and storage capacity, inventory levels, organizational structures and problem solving strategies. If there is a failure, for example to a deterioration of the rail mode, the condition will change and adjust it automatically for the freight village. The system allows not only the necessary process adjustments, but also shows recovery measures that are able to compensate the consequences of an incident as quickly as possible. This dynamic reaction concerning supply bottlenecks in freight villages cannot be achieved by current emergency plans which are often inadequate and rigid.

Project Leader LogDynamics: Prof. Dr. Hans-Dietrich Haasis

» www.preparednet.isl.org

» www.isl.org/en/projects/prepared-net

RFID-based Automotive Network (RAN)

More Transparency for the Automobile Industry

In January 2010 the research project RAN was launched as a part of the technology programme "Autonomik – Autonomous, simulation based systems for small and medium-sized enterprises“ by the Federal Ministry of Economics and Technology. With a funding of 23 Million Euros rendered by the ministry and by adding up the numbers of the project partners it raised a budget of 46 Million Euros in total. The project concluded successfully in December 2012.

New industry standards were set by the consortium made up of renowned automotive manufacturers, logistics companies, suppliers, technology partners, IT companies and research institutions. Developing methods and approaches to control order processing across-companies, the attention was set on the use of RFID technology as a future-oriented way to mark transport devices and goods. As a result of the project, the “Infobroker” allows every partner in the complex production- and logistics networks of the automobile industry to access exactly the information which is currently required. Data transfer proceeds close to real-time and thus images the material flow with high transparency. In this way and by the use of specifically developed assistance-systems users are enabled to control production and logistic processes more efficiently.

Project Leader LogDynamics: Prof. Dr.-Ing. Bernd Scholz-Reiter

» www.autoran.de

In January 2010 the research project RAN was launched as a part of the technology programme "Autonomik – Autonomous, simulation based systems for small and medium-sized enterprises“ by the Federal Ministry of Economics and Technology. With a funding of 23 Million Euros rendered by the ministry and by adding up the numbers of the project partners it raised a budget of 46 Million Euros in total. The project concluded successfully in December 2012.

New industry standards were set by the consortium made up of renowned automotive manufacturers, logistics companies, suppliers, technology partners, IT companies and research institutions. Developing methods and approaches to control order processing across-companies, the attention was set on the use of RFID technology as a future-oriented way to mark transport devices and goods. As a result of the project, the “Infobroker” allows every partner in the complex production- and logistics networks of the automobile industry to access exactly the information which is currently required. Data transfer proceeds close to real-time and thus images the material flow with high transparency. In this way and by the use of specifically developed assistance-systems users are enabled to control production and logistic processes more efficiently.

Project Leader LogDynamics: Prof. Dr.-Ing. Bernd Scholz-Reiter

» www.autoran.de

Autonomous Groupage Traffic

From Research into Practice

In groupage traffic, several orders with less-than-truckload (LTL) shipments are served by the same truck to decrease total cost. The complexity of process planning is even increased by changing amounts and individual qualities of shipments like weight, volume, priority and value. Handling the complexity in real situations is aggregated by the high degree of dynamics that result from unexpected events. The exact amount and properties of shipments are not known in advance. Actual capacities are only revealed while serving tasks. Further, undelivered loads in pre-carriage decrease truck capacities in onward carriage. To react to changing traffic conditions and delays on incoming goods departments, it is essential to adapt tours and timetables while regarding actual capacities.

Autonomous logistic processes enable efficient solutions for complex problems in dynamic environments. The transfer project “Autonomous Groupage Traffic” of SFB 637 and the Bremen office of Hellmann Worldwide Logistics GmbH & Co. KG investigates decentralized, autonomous processes for supporting planning and controlling of logistic companies. The goal is to enhance the dynamic processes with adaptive, reactive system behavior to increase the service quality through short transit times as well as reliable deliveries. In addition, both carriers and dispatchers should be supported with tour and routing proposals.

Project Leader LogDynamics: Prof. Dr. Otthein Herzog

» www.sfb637.uni-bremen.de

In groupage traffic, several orders with less-than-truckload (LTL) shipments are served by the same truck to decrease total cost. The complexity of process planning is even increased by changing amounts and individual qualities of shipments like weight, volume, priority and value. Handling the complexity in real situations is aggregated by the high degree of dynamics that result from unexpected events. The exact amount and properties of shipments are not known in advance. Actual capacities are only revealed while serving tasks. Further, undelivered loads in pre-carriage decrease truck capacities in onward carriage. To react to changing traffic conditions and delays on incoming goods departments, it is essential to adapt tours and timetables while regarding actual capacities.

Autonomous logistic processes enable efficient solutions for complex problems in dynamic environments. The transfer project “Autonomous Groupage Traffic” of SFB 637 and the Bremen office of Hellmann Worldwide Logistics GmbH & Co. KG investigates decentralized, autonomous processes for supporting planning and controlling of logistic companies. The goal is to enhance the dynamic processes with adaptive, reactive system behavior to increase the service quality through short transit times as well as reliable deliveries. In addition, both carriers and dispatchers should be supported with tour and routing proposals.

Project Leader LogDynamics: Prof. Dr. Otthein Herzog

» www.sfb637.uni-bremen.de